- John Wellwood

- August 12th, 2021

A change is as good as a rest, as the old saying goes. However, anyone who has experienced a period of change at an organisation will appreciate that while change may be invigorating in the long-term, when you are deep in the midst it’s anything but restful.

The same holds true with a Lean Six Sigma implementation. The long-term benefits of a deployment do little to assuage the fears and concerns of people when the first changes start to take place. For this reason, generally speaking the biggest barriers a business will face when they begin to implement Business Improvement is the human factor.

In spite of this, when a new solution doesn’t work, it is often the solution that is considered at fault. After all, if it appears to be the only variable in the situation, it’s a logical step to jump to. But this discounts the huge impact people can have on their working environment. To be successful a new solution has to be technically excellent, but it must also be accepted by the workforce.

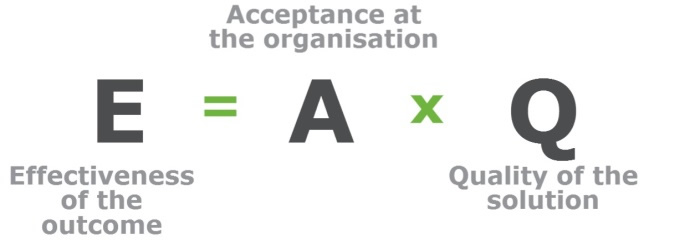

This can be expressed as an equation.

Effectiveness equals acceptance and quality

With a wealth of new tools and technology, as well as tried and tested methodologies such as Lean Six Sigma which have the robustness to identify root causes of problems, quality of the solution is rarely the barrier to change anymore. Seth Marrs, GM Salesforce Enablement at GE Healthcare, explained this phenomenon in an interview with the Process Excellence Network.

“Now you have tools like salesforce.com where I can reinvent the process in a week and I can roll it out just as fast so I am not limited by the technology anymore. I can change my process as fast as I can change my sales team.

“Now the ability of the people doing the work to change becomes your limiter rather than your ability to improve a process – which is something we have never had before.”

The same can be seen in Lean Six Sigma implementations. It is not the effectiveness of the new solution, or solutions, that are limiting the success at organisations. Instead it is the human factor.

Overcoming low engagement

This human factor comes in many forms but displays itself as a lack of acceptance and support. Jessica Fraser, Corporate Cost Accountant at Bornstein Seafoods Inc, has seen with Business Improvement herself.

“I think one of the biggest barriers can be lack of support from all members of the management team. The idea of Lean, Six Sigma, or any other quality/process improvement programme may sound great, but if the individual managers aren’t excited about the idea it will be very hard to get other employees on board.”

Her comments were echoed by Bob Garton, of Dennis Associates who said: “In my experience it is a lack of commitment and understanding by leadership in the first place. Most leadership teams see Lean Sigma as a set of tools only, which will miraculously transform their organisation. What they fail to get, is that they need to lead by example.”

However, this acceptance can be tackled, but it takes work. Engagement across a workforce is challenging even in organisation not undergoing cultural change, so improving engagement in change climate is tough. “Programmes like this require lots of time, training, and encouragement,” added Ms Fraser.

Generally engagement has to come from the top down, but it is also important to ensure the key influences are on board too. It is worth noting that while there is often some overlap, senior managers and key influencers are not always one and the same. Employees may often be more open to ideas that are promoted or supported from colleagues they respect and admire, rather than those they report to directly. Those driving a Lean Six Sigma implementation need to be aware of these human barriers, and ensure they take time to overcome them.

Because your new solution is only as good as the number of people who are actually happy to use it.

100% Effective can help you work with internal customers to increase engagement, get in touch to find out how we can help.