- Philippa McIntosh

- June 09th, 2015

A lot has been made recently about the sluggish productivity levels in the UK, and how this is a large contributor to the flat economy. Mark Carney, the governor of the Bank of England, mentioned the impact of productivity levels on his decision to downgrade the UK’s growth forecast.

We all know business efficiency is important and increases productivity, but how do you actually do it?

Firstly, it is important to determine what we are measuring as efficiency. A common definition is that a company can be considered efficient when it is using the lowest amount of inputs to achieve the greatest level of outputs without sacrificing quality.

Next, businesses need to determine why their output levels are where they are currently, and what changes they can make to improve them. This involves getting an accurate picture of the whole process.

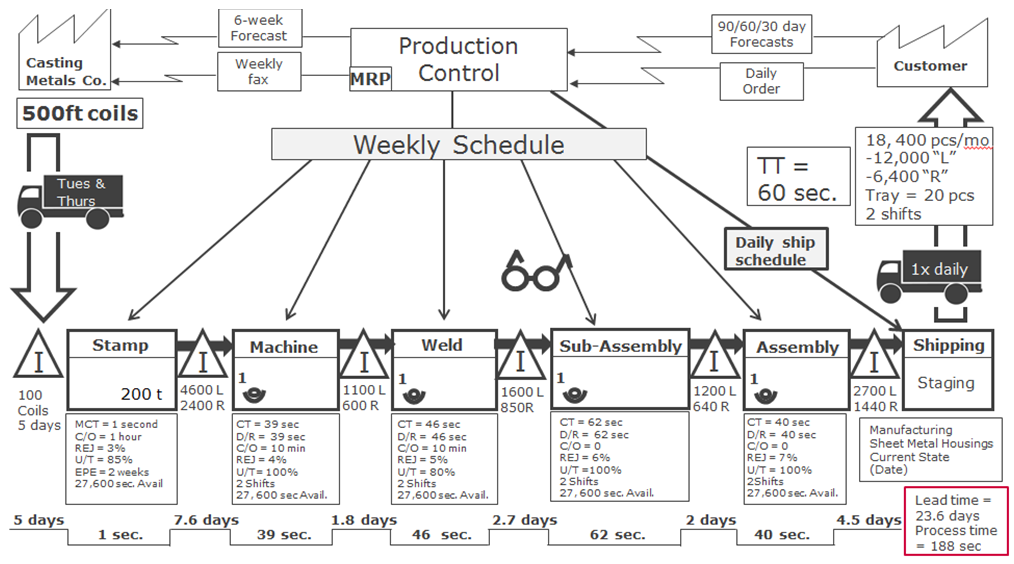

For this step we don’t think anything will give you better clarity than a detailed process map, and a Value Stream Map is particularly good at this. The clue in the title tells you that this map highlights where the value is in your process and, the flip side of that, where the waste is too.

Current State Map

This example above shows a manufacturing process which takes over 23 days (red box, bottom right) but only 188 seconds of that is adding value. Less than four minutes of a month-long process adds value for the customer.

The process above has a Process Cycle Efficiency of 0.009%, when businesses should be aiming for the 5% mark (or ideally higher).

Fortunately, the Value Stream Map also indicates where the biggest contributors to a long lead time are, so you can take steps to eradicate them. In this example we can see that the Stamping and Machine steps are adding 12.6 days to the process, but contributing just 40 seconds of value, so that is probably a good starting point.

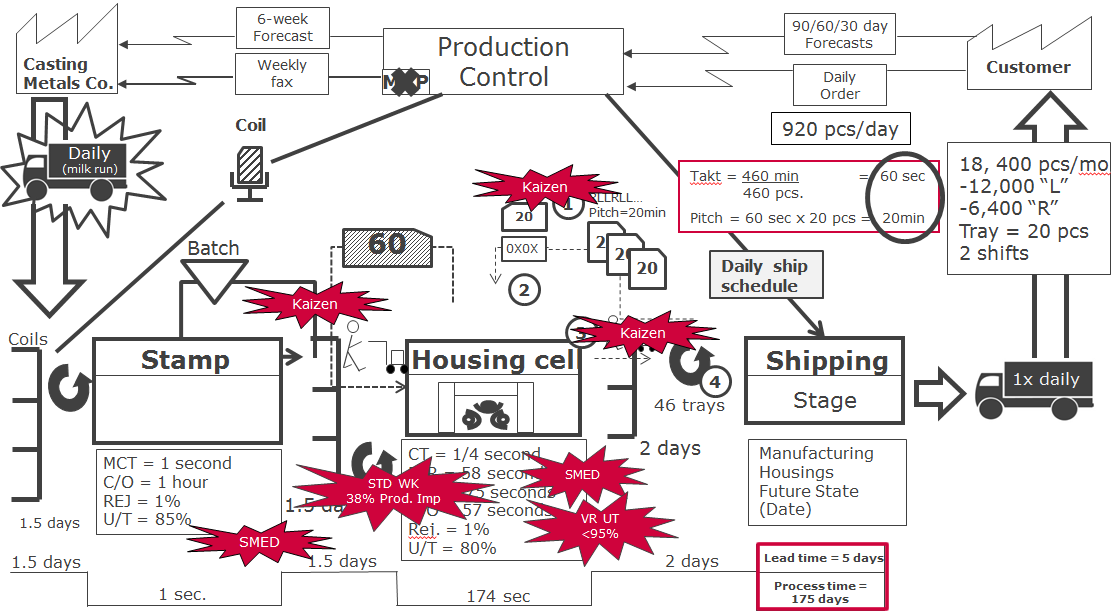

Before you get started on making changes, your next step should be create a Future State Map. This is an ideal version of the process, how long it should take if you make all the improvements you can. It shows you what is possible, gives you something to aim for and, most importantly, gives you a list of things you can do in order to make the improvements.

We can see the exact same process on the map above, however now it process takes just five days, while the value added time has only dropped to 175 seconds.

Future State Map

Boosting business efficiency is a simple equation of reducing lead time to increase productivity. However, it is anything but easy! Taking a systematic approach to identifying waste, deciding on your projects and putting an implementation plan in place will increase your chances of success. So will having the skills generated from Lean Six Sigma training.

If you want to talk to us about how we can help you improve efficiency yourself, get in touch on 0800 066 3749.