- Apprenticeships

- Training Courses

- Lean Six Sigma

- Lean

- Introduction to Lean

- Lean Practitioner Training

- Lean Kaizen Facilitator Training Course

- Lean Mistake Proofing Training

- Lean 5S Training Course

- Lean 8 Wastes Training Course

- Lean Library (47)

- Lean Bundle (10)

- Failure Mode and Effects Analysis (FMEA) Training

- Problem Solving Training Course

- All Lean Courses

- Business Improvement

- Personal Development

- Facilitation Body Language Training

- Building Self-Esteem & Assertiveness Training

- Influencing Skills Training

- Negotiation Skills Training Course

- Building Your Personal Brand

- Active Listening Skills Training

- Stress Management Training

- Online Pressure Management Training

- All Personal Development Courses

- Management Development

- All Courses

- Consultancy / Coaching

- Resources

- E-Learning

- About Us

- Contact

Improvement Leader Apprenticeship Level 6 Lean Six Sigma MBB

- Improvement Leader full Lean Six Sigma Master Black Belt certification included

- Developing improvement strategies and providing leadership in improvement for a business.

- Duration – 18 Months

- Support by dedicated Master Black Belt

- 20 training days, coaching, certification support

- Open or in house cohorts to choose from

- Cost - £15,000 Apprentice levy or only pay £750 with government grant*

*Improvement Leader Apprenticeships are funded by a co-investment arrangement which is 95% Government funded and 5% Employer contribution. This means that a Level 6 (Master Black Belt) would cost you between £0 – £750.

Organisations today are navigating unprecedented changes. Following the pandemic, teams are adapting to remote or hybrid work environments, increased needs for productivity improvements and increasing customer demands. This period is happening alongside other major shifts, including digital transformation, enhancements in sustainability and challenges in recruitment. As these changes impact businesses across the spectrum, there is a critical need for reliable and skilled leaders to champion and drive improvement and ensure stability.

Managing Business Transformation equips your leaders with the essential skills to drive improvement and strategic change.

Improvement Leader Level 6 - Entry Requirements

This advanced apprenticeship requires applicants to meet certain criteria. Employers should select candidates who are in positions to drive significant organisational change. Candidates must have the time and capacity to commit to the training program and fulfil the requirements for the final assessment.

Professional Experience and Business Position:

Applicants are expected to have at least two years of practical experience in roles that involve managing and implementing improvement or transformation projects.

Participants in this program must hold a position that enables them to apply the principles of the Improvement Leader Apprenticeship effectively and where they can acquire substantial new skills. An initial assessment during the application process will evaluate suitability based on these criteria.

In their CVs and personal statements, applicants must demonstrate at least two years of professional experience in a minimum of three of the following areas (not listed in order of importance):

- Leadership or management of individuals or teams in improvement activities.

- Training, coaching, or mentoring individuals or teams in improvement activities.

- Design and evaluation of training solutions that enhance organisational capabilities in improvement principles, methods, and tools; including assessing needs and selecting candidates for various training levels.

- Leadership or facilitation in project management and change management tools and techniques.

- Utilisation of improvement methodologies to develop new processes, products, or services and advising on the selection of appropriate improvement methods.

- Expertise in process mapping, analysis principles, and tools.

- Skills in data acquisition planning, data analysis, and statistics, including guiding others in these areas.

- Identification and prioritisation of new opportunities within a portfolio of multiple improvement projects.

- Guidance on planning, analysing, and interpreting experiments, including planning and optimizing both comprehensive and fractional experiments.

- Application of problem-solving methods, ideally at the Lean Six Sigma Black Belt level.

Candidates who are already certified as Lean Masters, Senior Lean Leaders, Senior Navigators, Lean Six Sigma Master Black Belts, or Senior Consultants are not eligible.

English and Maths Requirements:

To successfully complete the apprenticeship, participants must have Level 2 qualifications in English and maths (i.e., GCSEs at Grades 9-4 or A*-C, or equivalent).

Improvement Leader Level 6 apprenticeship programme?

Improvement Leaders play a critical role in formulating improvement strategies, leading organisational improvement initiatives, and mentoring Improvement Specialists in sophisticated analytical techniques. Typically reporting to Board members or Heads of Department, Improvement Leaders manage (both directly and in a matrix structure) a team of Improvement Specialists who implement the strategy and oversee improvement projects. They collaborate extensively with various business functions to facilitate the establishment and realisation of business objectives. Often, they are responsible for improvement endeavors associated with the most significant and high-priority work programs within the organisation.

Improvement Leader Apprenticeship certification will

- Enable managers to lead complex change initiatives amidst evolving business conditions.

- Develop organisational capacity by training operational improvement leaders to spearhead change and transformation.

- Provide learners with globally recognised skills in project and change management, along with Lean Six Sigma principles.

- Cultivate confident leaders who inspire others to advocate for change.

- Implement impactful work-based projects that facilitate immediate organisational change.

- Equip individuals with the ability to address complex data challenges across various business sectors.

To ensure that you gain hands-on experience, you will spend at least 20% of your time, approximately 6 hours per week, working on business improvement projects, developing confidence, skills, and problem-solving abilities to become a certified lean six sigma level 6 apprentice.

Coaching sessions and gate reviews with sponsors will be provided to ensure that major and minor projects are completed successfully. This will not only demonstrate your learning but also the application of your learning, which will be valuable to your current and future employers.

Why choose 100% Effective for your Improvement Leader Level 6 Master Black Belt Training?

- 25 years of delivering high quality strategic Improvement training, consultancy, coaching and advice as improvement specialists

- Learn from Award winning Tutors, Master Black Belts and Leaders with global experience with some of the world’s leading companies – learn from the best

- As improvement specialists we are uniquely equipped to guide you to become an improvement leader in any industry. We pride ourselves in training our competition from large consultancy firms to individual Master Black Belt but why train with them when you can train with their coaches.

- Bespoke modules, support, training and coaching to suit your business requirements and personal restrictions. We can adapt to suit your needs

- Blended learning. Our approach uses true blended learning – coaching, virtual and face to face training, online courses, case studies, simulations, teach backs, individual and group exercises and numerous resources for all modules of your course needs

- Your apprentices will complete 2 major and several minor projects providing Return on Investment quickly providing Measurable business improvements

- Each learner is given E-Learning backup with full LSS Black Belt course and multiple other E-Learning titles for 2 years.

- We offer a customized program for your apprentices that includes blended learning – a mix of virtual, face-to-face, and e-learning methods. To enhance their learning experience, we utilize a variety of exercises, simulations, teach-backs, games, and projects.

- Continuous 360-degree reviews of your progress with you, your line manager and your dedicated Master Black Belt tutor

- You will be certified as a Lean Six Sigma Master Black Belt as well as an Improvement Leader Apprenticeship

- We will support not just the Improvement Leader Apprentice but also their line managers, supervisors and senior managers if required

- We are educators who pride themselves of providing return on investment through project completion

Who is the Improvement Leader standard designed for?

Continuous improvement is essential for any organisation’s growth and should be spearheaded by professionals skilled in Lean Six Sigma and Project and Change Management. This qualification is designed for improvement leaders who are found in all sectors and functions, including Automotive, Pharmaceutical, Telecommunications, Retail, Finance, Food and Beverage, Travel, and Leisure.

Typical roles and responsibilities:

- Developing Improvement strategy and providing leadership in improvement for the business

- Developing processes and resources to support improvement strategy deployment such as guidance for structured project reviews

- Training, coaching and mentoring Improvement Specialists and senior stakeholders

- Designing and sourcing training solutions for the business

- Leading large-scale, complex Improvement activities and Sustainability (Improvement or Sustainability activities)

- Managing a team of Improvement Specialists

- Improvement Leaders have high-level expertise in Lean, Six Sigma, Project and Change management and are recognised as the specialists in leading improvement strategy.

For more information about the Improvement Leader Level 6 standard, please visit the following link: https://findapprenticeshiptraining.apprenticeships.education.gov.uk/courses/405

Company support requirements for Improvement Leader Level 6

Off-the-Job Training

Apprentices are required to dedicate at least six hours per week to off-the-job training. This essential element of the apprenticeship program must be facilitated by the employer. Both the apprentice and the employer must collaboratively schedule this training within the apprentice’s paid work hours. Off-the-job training encompasses more than just workshops, coaching, and online study sessions. It also includes:

- Practical training such as shadowing, mentoring, and industry visits.

- Participation in or leading meetings not related to usual job responsibilities.

- Time allocated for learning support and assignment writing.

- Meetings with apprenticeship tutors and coaches.

- Development of projects for their evidence portfolio.

Line manager support

The line manager plays a crucial role in supporting the apprentice. We will collaborate with them to provide a clear understanding of the program’s details, learning formats, and the necessities of off-the-job training. Line managers will also participate in selecting significant work-based projects, coordinating meetings with the apprenticeship learning coach, and assigning mentors to apprentices if needed. Additionally, line managers or other senior managers will act as sponsors for MBB projects and attend monthly updates.

How is this Improvement Leader Level 6 program delivered?

At 100% Effective, we offer two ways to become an Improvement Leader through our apprenticeship program.

- Our courses are available every quarter in open cohorts, which are delivered virtually.

- Alternatively, we offer in-house programs using a blended learning approach.

With over 25 years of experience in blended learning, we have the expertise and resources to provide face-to-face, virtual, and eLearning delivery. Our virtual approach allows us to train and coach apprentices from anywhere in the country, reducing travel costs and minimising lost productive time.

For your Improvement Leader, you will receive:

- 20 Virtual Training days spread throughout the programme

- Monthly coaching sessions and progress checks with your dedicated MBB

- Support to deliver improvement projects as part of your portfolio of evidence

- Receive support with 12 gate reviews and sponsor sessions

- Receive 8 hours of end point assessment support

- If you wish the ability to join any of our virtual Green or Black Belt Lean Six Sigma training courses to offer refresher training

- Group exercises to apply and reflect on your learning

- Access to an Online eLearning library of courses to support your learning and certification

- Support to write your dissertation as well as a case study and marketing collateral as part of your course

How will Improvement Leader apprentices be assessed?

The End Point Assessment (EPA) process starts once the employer confirms that the apprentice is consistently working at or above the level specified in the occupational standard, the gateway requirements for EPA are met, and evidence can be provided to an EPAO. The gateway requirements include the following:

- Evidence of English and mathematics at level 2, as a minimum

- A Portfolio of evidence (see below)

- A 4000 to 4500 word dissertation which is the basis of a professional

Portfolio of evidence required for Improvement Leader Master Black Belt Level 6 Apprenticeship

- The portfolio of evidence must include a minimum of one set of evidence for each of key the topic areas associated with the Apprenticeship

- The above evidence must include a range of documents such as Minitab screen shots of regression analysis, coaching reports and a 1-page summary from the Lean strategy

- The portfolio of evidence must also include evidence relating to the preparation and delivery of a training session to black belt level with at least 2 of these subject areas

- Project and Change Management, Lean Principles and Tools, Measurement System Analysis and Data Collection Planning Graphical Analysis and Statistical Analysis, Data Transformation and Process Capability, Experimentation, Optimisation and Modelling, Failure Mode Avoidance

- The training materials must be prepared by the apprentice (they must not deliver published training material prepared by someone else and this requirement will be authenticated by a signed statement provided by the apprentice’s employer) and included in the portfolio of evidence

- The training session must be delivered to a group of Level 5 black belt delegates in their normal working environment and last 45-50 minutes in duration and be videoed.

- Training materials may include for example PowerPoint presentation, lesson plan, training notes, photographs of white boards, handouts, flipcharts

- All training materials and records of delegate feedback must be included in the portfolio of evidence

The EPA consists of two distinct assessment methods:

- Professional discussion, underpinned by portfolio of evidence

- Dissertation, presentation and questioning

Professional discussion, underpinned by portfolio of evidence

- This must be a discussion between the apprentice and their assessor, with a technical expert from the apprentice’s employer present. The technical expert’s role is to provide the assessor with clarifications around specific company policy and procedure or technical knowledge only. They must not provide information on behalf of the apprentice, ask the apprentice questions or influence the apprentice in any way. The technical expert must not amplify or clarify points made by the apprentice. Note that the EPA judgement lies solely with the assessor who grades the professional discussion.

- It must last 2-hours to 2-hours 20 minutes in duration.

- Assessors must ask open/competency based questions to cover the Knowledge, skills and behaviours outlined in the standard

- Apprentices may refer to the portfolio of evidence when answering questions.

Dissertation, presentation and questioning

- Apprentices must produce a dissertation during the EPA period, which will be the basis of a presentation to the apprentice’s assessor and a technical expert from the apprentice’s employer, with follow up questioning immediately after the presentation.

- The main body of the dissertation must be 4,000 to 4,500 words. A summary and appendices must be included, additional to the word count. The summary must be a concise one-page of A4, visual, follow the principles of ‘A3 Thinking’ and convey key points in a way that enables messages to be grasped ‘within 3 seconds.’ Appendices must contain supporting evidence, such as meeting minutes, extracts from business strategy, key performance indicator dashboards, risk log and organisation charts (not included in the word count).

- The dissertation must focus on the development and deployment of improvement strategy in their business and of sufficient scope to demonstrate the knowledge and skills as set out in the standard.

- The presentation must be 45 to 50 minutes in duration.

- The presentation must be followed by questioning lasting 35 to 40 minutes.

What advantages can your company gain by training Improvement Leader MBB apprentices through our program?

Why train your staff as Improvement Leader Apprentices / Lean Six Sigma Master Black Belts?

- Develop a business improvement leader capable of driving significant change and transformation in your business

- Build the capability and technical skills needed to lead teams through change and transformation

- Prepare employees to manage unprecedented changes and improvements in your organisation

- Develop confident leaders who can inspire and encourage action during periods of growth, disruption or uncertainty. Support a culture of innovation through leading by example. As well as addressing challenges across different aspects of the organisation

- Deliver significant savings through project completion linked to your strategic goals – solve problems permanently

- Demonstrate your commitment to staff develop – They will receive internationally recognised qualifications – Improvement Leader Apprenticeship, Lean Six Sigma Master Black Belt, Certificate in change management and others

- Costs – use your levy or receive 95% funding

- Obtain support for your staff from internationally recognised Master Black Belt from 100% Effective through training, coaching and support for 18 months

What advantages can individuals gain by training as an Improvement Leader Master Black Belt apprentice?

Learners who complete this programme will become capable leaders who can:

- Earn not only an Improvement Leader Apprenticeship Level 6 but also the highest level of Lean Six Sigma Certification Master Black Belt status. MBB’s are highly respected and sought-after people demanding high salaries globally

- Become a catalyst for improvement and operational excellence and act as a role model for others and gain the opportunity to influence strategic direction and change in your company

- Develop and demonstrate personal resilience and learn how to challenge, influence and engage senior stakeholders.

- Turbo boost your career with knowledge, certification as well as application of leadership, change management and improvement skills. Become one of a tiny % of people in the world who are MBB certified

- Network with other highly engaged and effective Improvement Managers as part of your course

Improvement Leader Master Black Belt apprentice Outcomes

Participants who successfully complete this program will become proficient leaders capable of:

- Training and coaching personnel at all levels of business improvement to achieve permanent problem resolution.

- Planning processes and allocating resources effectively to support the deployment of improvement strategies.

- Creating a sustainable transformation strategy that integrates Lean and Six Sigma methodologies.

- Designing and procuring appropriate training solutions tailored for your organisation.

- Leading extensive and complex improvement or sustainability initiatives.

- Assisting colleagues in applying theoretical knowledge and conducting graphical or statistical analyses to projects and tasks.

Improvement Leader MBB Course Content

Improvement Leaders are responsible for developing improvement strategy, providing leadership in improvement for the business and for coaching and supporting Improvement Specialists in advanced analysis. The Improvement Leader Level 6 typically reports to Board members or Heads of Department and manages (directly and/or matrix) a team of Improvement Specialists, who deploy the strategy, and lead improvement projects. They work closely with all functions of the business to support the setting and achievement of business goals, often accountable for Improvement activities within the largest-scale and highest priority programmes of work.

Improvement Leaders Level 6 possess knowledge and understanding of the following areas:

- Strategy development: Policy deployment principles and Hoshin Kanri Porter’s 5 forces, Strengths Weaknesses Opportunities Threats (SWOT)/Political Economic Social Technological Legal Economic (PESTLE), Ansoff’s growth matrix, Boston Consulting Group growth share matrix, GE-McKinsey matrix

- Business benefits: Net present value, activity based costing

- Team formation & leadership: Team types and constraints, dysfunctional teams, emotional intelligence, Neuro-linguistic programming techniques, reinforcement strategies

- Self-development: Latest thinking in Continuous Improvement and Operational Excellence

- Presentation and reporting: Single page reporting – A3 thinking

- Project selection and scoping: Business performance metrics

- Measurement systems: Audit Measurement System

- Data analysis – statistical methods: Regression (multiple & binary logistic), forecasting and queuing theory

- Experimentation and optimisation: Monte Carlo and Discrete Event simulation. Balanced and unbalanced designs, General Linear Model

Improvement Leader will learn the following core skills throughout their training:

- Strategic deployment of continuous improvement

- Business benefits: Identify, quantify and communicate financial and non-financial benefits

- Team formation and leadership

- Capability Development: Design, source and evaluate learning interventions

- Project management

- Presentation and reporting: Critique own and others’ improvement reports/presentations

- Change management: Assess the effectiveness of change and identify opportunities to improve outcomes, guiding and supporting others to deliver results

- Principles and methods: Clearly communicate the importance of appropriate method-selection to others, and enable the organisation to make appropriate decisions through learning and tools

- Project selection and scoping: Establish guidelines for project identification and prioritisation

- Problem definition: Promote importance of evidence-driven problem definition in everyday work

- Voice of Customer(VOC): Coach others on the importance of understanding VOC. Identify ways that an organisation can improve customer insight through feedback loops to enable improvement activities to be focused appropriately

- Process mapping and analysis: Apply process thinking to identify opportunities to improve business and process performance and maintain ongoing process control

- Lean concepts and tools: Easily translate and communicate fundamental Lean concepts for application to a wide range of business functions. Assess the effectiveness of a Lean strategy and make recommendations for improving outcomes

- Data acquisition for analysis: Assess data acquisition conducted by others in terms of tool selection and application, conclusions and recommendations

- Statistics and graphical analysis: Assess and guide graphical and statistical analysis conducted by others in terms of tool selection and application, conclusions and recommendations

- Process capability and performance: Make recommendations on how an organisation can drive improvement through the selection of tools and metrics for process capability analysis

- Root cause analysis: Guide and coach others in planning to ensure efficiency of approach

- Experimentation, optimisation and simulation: Support the building of mathematical models and exploitation of these

- Identification & prioritisation: Develop a Creative Thinking strategy to support improvements

- Failure Mode Avoidance: Communicate the business case, aims, methods & key tools

- Data analysis – Statistical Process Control: Make recommendation on how an organisation can drive sustained improvement through the application of Statistical Process Control

- Benchmarking: Develop a benchmarking strategy to support an improvement programme

Improvement Leaders demonstrate the following Behaviours:

- Drive for results: Be a primary advocate for Improvement and Operational Excellence acting as a role model for others, focused on improving customer experience and delivering benefits

- Team Working: Actively seeks opportunities for improving team performance and coaches others to resolve under-performance issues

- Professionalism: Demonstrates personal resilience. Challenge, influence & engage seniors

- Strategic Thinking: Drives future thinking for themselves and others. Actively seeks out new ideas, opportunities methods and tools. Build a knowledge and best practice sharing network

- Safe Working: Recognises opportunities to improve safe working practices

Improvement Leader meet the Program Directors

Your Apprenticeship will be delivered by 2 highly experienced Improvement Leaders and Master Black Belts with international experience working with global companies as well as SME’s.

John Wellwood

John Wellwood an award-winning author on Lean Six Sigma deployment has been training, advising and coaching for over 30 years. He was the global Improvement lead for BTR Industries a £12 billion company as well as the operations director for a UK automotive company.

John specialises in Improvement deployment and organisational change. He has presented at the British library to international leaders as well as at the International Lean Six Sigma Summit. His training and coaching experience has seen him advise companies on 4 continents including major manufacturing, pharma, food, legal, service and health companies in Lean and Lean Six Sigma deployment.

Training is John’s passion and he has developed countless courses and presentations that are the basis of our online library used in the learning program.

Mike Tichen

With over 20 years’ experience in Lean Six Sigma, Mike is one of the most highly respected Master Black Belts delivering training in the UK today. He began his Lean Six Sigma and operational management career in 1995 while working for GE Lighting, and has been working to spread Business Improvement best practice since. After leaving GE, he worked for Alstom Transport, Textron, Norwich Union and SigmaPro, before joining 100% Effective as a Senior/Lead Consultant in 2013. Throughout his career he has consistently delivered projects with multi-million pound savings, and has continued to mentor and coach others in Lean Six Sigma. Since he began delivering Lean Six Sigma training, Mike worked tirelessly to enhance learning with the very best approaches to teaching and knowledge retention. This culminated with the creation of our unique blended training materials which offer one of the most robust and high-quality online courses available in the UK.

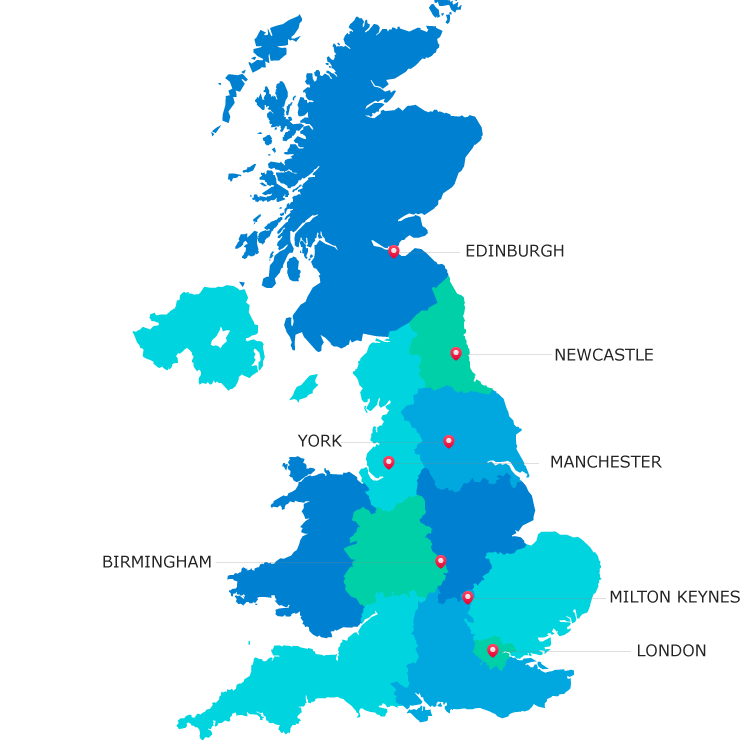

Our Most Popular Locations

Our Six Sigma, Lean and Kaizen classroom training is available in major locations, towns and cities across the UK. Here’s where we get the most demand.

Contact us

General Enquiries

Want to place an order, or need more information on one of our courses?

Live Chat

Want to place an order, or need more information on one of our courses?

- Start Chat

Our address

1 Parkview Court, St Pauls Road, Shipley, West Yorkshire, BD18 3DZ

- Company # 4407150 VAT # 801793338

Contact hours

Monday – Friday: 8.30am – 5pm

- Excluding public holidays

Blogs & Articles Improvement Leader Level 6 Master Black Belt

News, insights and infographics