- Apprenticeships

- Training Courses

- Lean Six Sigma

- Lean

- Introduction to Lean

- Lean Practitioner Training

- Lean Kaizen Facilitator Training Course

- Lean Mistake Proofing Training

- Lean 5S Training Course

- Lean 8 Wastes Training Course

- Lean Library (47)

- Lean Bundle (10)

- Failure Mode and Effects Analysis (FMEA) Training

- Problem Solving Training Course

- All Lean Courses

- Business Improvement

- Personal Development

- Facilitation Body Language Training

- Building Self-Esteem & Assertiveness Training

- Influencing Skills Training

- Negotiation Skills Training Course

- Building Your Personal Brand

- Active Listening Skills Training

- Stress Management Training

- Online Pressure Management Training

- All Personal Development Courses

- Management Development

- All Courses

- Consultancy / Coaching

- Resources

- E-Learning

- About Us

- Contact

Lean Six Sigma Green Belt Improvement Practitioner Apprenticeship

- Duration – 14 Months

- Full Lean Six Sigma Green Belt certification

- Support by dedicated Master Black Belt

- 10 training days, coaching, certification support

- Optimised for all devices

- Access to 100% Effective’s Alumni

*Improvement Practitioner Apprenticeships are funded by a co-investment arrangement which is 95% Government funded and 5% Employer contribution. This means that a Level 4 (Green Belt) would only cost you between £0 – £300.

Home / Apprenticeships / Improvement Practitioner Level 4 Apprenticeship Lean Six Sigma Green Belt

With our extensive experience in Lean Six Sigma training and coaching dating back to 1999, 100% Effective excels as Business Improvement Specialists perfectly positioned to offer the Improvement Practitioner Apprenticeship Level 4 program. This comprehensive program, enriched by our Master Black Belts (MBBs) with substantial hands-on expertise, empowers learners through tailored training and coaching. Our MBBs’ mentorship ensures project completion, enabling apprentices to acquire essential skills and behaviors while swiftly delivering a tangible return on investment for employers.

At 100% Effective, our Level 4 Improvement Practitioner Apprenticeship training equips learners with the comprehensive skill set required for international Lean Six Sigma Green Belt certification, coupled with change management expertise, fostering apprentices who are adept at both problem-solving and implementation. Our pragmatic approach ensures that every facet of our program caters to the needs of both learners and employers, guaranteeing mutual satisfaction. With a commitment to alignment, our in-house programs are adaptable to your unique culture, history, and objectives, further enhancing the relevance and impact of our training.

Improvement Practitioners Green Belt Apprenticeship - What Pre-Requisite qualifications are needed?

To complete their certification, Improvement Practitioners will need to have achieved a Functional Skills Level 2 in both English and Maths. This is equivalent to a GCSE Grade 4 (or C grade in the previous system). If you have not obtained these levels, then we can support you to achieve them.

Why should you choose 100% Effective for Lean Six Sigma level 4 apprenticship?

- We at 100% Effective are improvement specialists, supporting companies and learners since 1999.

- Your apprentices will be trained and coached by the same highly experienced Master Black Belt coaches and trainers.

- Your apprentices will obtain an internationally recognized Lean Six Sigma Green Belt certification along with other certifications on top of your apprenticeship, including change management and health and safety.

- Your apprentices will obtain an internationally recognized Lean Six Sigma Yellow Belt within the first month of the apprenticeship.

- For line managers, sponsors, and supervisors, there is training on how to best support your learner

- Your apprentices will complete 2 major and several minor projects providing Return on Investment quickly providing Measurable business improvements

- Each learner is given E-Learning backup with full LSS GB course and multiple other E-Learning titles for 2 years.

- We offer a customized program for your apprentices that includes blended learning – a mix of virtual, face-to-face, and e-learning methods. To enhance their learning experience, we utilize a variety of exercises, simulations, teach-backs, games, and projects.

- Templates, guides, mock exams, case studies, and videos are used to make learning efficient and easier for everyone.

- You will also have access to our alumni so you can network with like-minded people

- We provide a personalized development plan for your apprentices to foster their growth and advancement.

What is the apprenticeship standard?

Improvement Practitioners use a combination of Lean and Six Sigma methodologies, project management, and change management principles and tools to identify and lead change across various organizational functions and processes. These practitioners can be found in all sectors and functions, including automotive, banking, engineering, food products, IT, property, retail, telecoms, local and county councils, NHS, voluntary/charity, utilities, pharmaceuticals, insurance, and hospitality.

Typically, Improvement Practitioners lead smaller projects and/or provide essential support in larger programs, addressing challenges that may require swift problem-solving or recurring issues that demand in-depth analysis and the implementation of effective and sustainable countermeasures. They serve as the main point of contact for all stakeholders and are responsible for project communication throughout the process.

Typical activities of Improvement Practitioners include:

- Identifying potential opportunities, diagnosing issues, proposing solutions, and implementing changes and controls.

- Coaching teams and sharing best practices.

- When leading projects, they may manage small teams to ensure motivation and momentum, and be responsible for successful project completion.

There are various job titles associated with this occupation, including but not limited to:

- Business Improvement Practitioner

- Continuous Improvement Manager

- Process Excellence Manager

- Lean Six Sigma Green Belt

- Quality Control Senior Analyst

Other job titles in this field may include:

- Environmental Compliance Manager

- Engineer (Environmental, Mechanical, Geotechnical, Civil, Chemical, etc.)

- Environmental Construction Management

- Environmental Data Analyst

- Environmental Health and Safety Officer

- Transportation Engineer

- Environmental Improvement Compliance Manager

- Environmental Improvement Engineer

- Environmental Improvement Construction Manager

- Environmental Improvement Data Analyst

- Environmental Improvement Health and Safety Officer

For more information, please visit the following link: https://www.instituteforapprenticeships.org/apprenticeship-standards/improvement-practitioner-v1-2

How is this program delivered?

At 100% Effective, we offer two ways to become an Improvement Practitioner through our apprenticeship program.

- Our courses are available every two months in open cohorts, which are delivered virtually.

- Alternatively, we offer in-house programs using a blended learning approach.

With over 25 years of experience in blended learning, we have the expertise and resources to provide face-to-face, virtual, and eLearning delivery. Our virtual approach allows us to train and coach apprentices from anywhere in the country, reducing travel costs and minimizing lost productive time.

For your Improvement Practitioner apprenticeship, you will

- Attend 10 days of training

- Receive 7 individual coaching sessions

- Attend 8 group discussions / cross presentations

- Receive support with 12 gate review and sponsor sessions

- Receive 8 hours of end point assessment support

- Have access to multiple mock exams

- Complete at least 10 additional eLearning courses

- Complete 1 major and 5 minor projects

- Write at least 1 article / case study

How will apprentices be assessed?

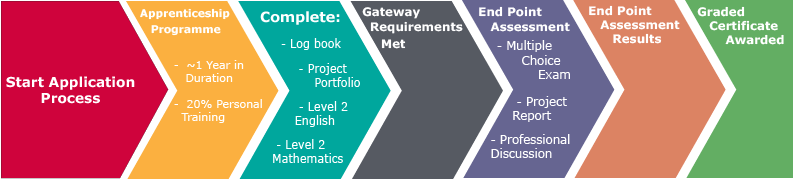

The End Point Assessment (EPA) consists of three distinct assessment methods:

- Multiple choice examination – to assess knowledge elements of the standard

- Project report, presentation & questioning – to holistically assess knowledge, skills, and behaviours (KSBs) in the standard

- Professional discussion underpinned by log – to holistically assess KSBs across the standard.

After you have met the Gateway requirements, we will hold a meeting with your sponsor and coach to determine if you are ready for EPA. If so, you will then be coached using mock exams and group work to become ready for the EPA.

The EPA is undertaken by an independent assessment organization chosen by your employer. After your multiple-choice exam, you will present your project portfolio of A3s and then participate in a professional discussion on your work during your apprenticeship. You will then promptly be given an overall grade of Fail, Pass, or Distinction by the End Point Assessment organization. 100% Effective will support your apprentices through the entire process.

Below is a visual representation of the process:

What advantages can your company gain by training apprentices through our program?

Savings of at least £50,000 per project – Based on our 24 years of experience in delivering Lean Six Sigma. We achieve this by providing multiple support elements for each apprentice, including regular coaching from Master Black Belts with years of experience, formal gate reviews with sponsors and coaches at the end of each DMAIC phase, and readiness discussions prior to the gateway to ensure success.

Each apprentice will also provide other Returns on Investment by completing minor projects to build an impressive portfolio prior to the gateway, as well as writing at least one article that can be used for internal communication and promotion.

Our learning experience is designed around your company and your objectives. Our flexible blended approach means we can support you in any way to meet your industry or business needs. Each apprentice will enjoy a tailored learning experience to maximize their learning and development.

We provide monthly reports on the progress of your apprentices and their major and minor projects, ensuring timely communication for any required internal reporting. We have reliable and professional trainers, coaches, and admin support, all led by a dedicated account manager.

Your apprentices will become more confident and effective. They will be able to identify issues, solve problems, and implement solutions

What can you expect during your Improvement Practitioner Apprenticeship?

The goal of this apprenticeship is to equip individuals with the necessary skills to identify problems within a company, devise effective solutions, and implement them successfully. The apprenticeship lasts for 14 months and requires dedication to develop both technical improvement skills and softer implementation change manager skills.

To successfully complete this improvement practitioner level 4 apprenticeship, you will need to undertake a major project that saves an average of £50,000, as well as several minor projects that contribute to improvements in staff and customer satisfaction, quality improvement, time reduction, cost reduction, and delivery improvement. To achieve this, you will attend training courses, coaching sessions, and individual and group project work and research, among other activities. You will work with sponsors, 100% Effective coaches, and other company personnel.

To ensure that you gain hands-on experience, you will spend at least 20% of your time, approximately 6 hours per week, working on business improvement projects, developing confidence, skills, and problem-solving abilities.

Coaching sessions and gate reviews with sponsors will be provided to ensure that major and minor projects are completed successfully. This will not only demonstrate your learning but also the application of your learning, which will be valuable to your current and future employers.

Throughout the lean six sigma level 4 apprenticeship, you will be exposed to real-world examples of tools, techniques, and approaches through case studies that will stretch your knowledge and challenge you to improve.

We will provide support to ensure that you pass your apprenticeship through discussions with your coaches, mock exams, portfolio discussion practice, and presentation advice prior to the end-point assessment.

Upon completion of the green belt apprenticeship, you will obtain an internationally recognized Lean Six Sigma certification, along with several other certificates of achievement such as change management and health and safety, to name just two. We only ask for your commitment for 14 months to enhance your learning and development.

Improvement Practitioner Apprenticeship Level 4 Green Belt Course Content

The Improvement Practitioner lean six sigma Level 4 Apprenticeship will cover a broad range of topics and models across the entire DMAIC process – Define, Measure, Analyse, Improve and Control. Our expert trainers and coaches will provide you with the key knowledge, skills and behaviours to effectively identify problems, solve them and then implement them. You will cover all the key aspects of Lean Six Sigma as well as change management and many other key skills required for any Improvement Practitioner. By the end of the apprenticeship, you will have gained the knowledge, skills, and behaviours outlined in the Improvement Practitioner Level 4 (Lean Six Sigma Green Belt) standard. These include the ability to effectively identify and solve problems, implement solutions, and utilize key aspects of Lean Six Sigma and change management.

Improvement practitioners possess knowledge and understanding of the following areas:

- Leading improvement teams: including personality types, team development stages, motivational techniques, situational leadership, learning styles, and mentoring models.

- Project planning: including multi-element business case, financial plan, benefits realization plan, risk management plan, and project plan.

- Project reviews and coaching: including coaching models and Maslow’s hierarchy of needs.

- Change planning: including change management methods, impact/readiness, and influencing strategies.

- Commercial environment: including business and economic risks that can impact all aspects of improvement, from project selection to implementation.

- Principles and methods for improvement: including improvement methods (e.g., Practical Problem Solving, Define-Measure-Analyse-Improve-Control, 8-Disciplines, Identify-Define-Optimise-Verify) across all functions, policy deployment principles, and Lean culture.

- Voice of the customer: including interviewing and focus groups, Quality Function Deployment principles, and how to build a House of Quality.

- Process mapping and analysis: including activity network diagrams, design structure matrix, process modelling, key function diagrams, and analysis.

- Data acquisition planning: including stratification, rational sub-groups, power and sample size.

- Statistics and measures: including probability distributions, confidence intervals, central limit theorem, how to test data for stability and normality, and strategies for dealing with non-stable or non-normal data.

- Lean concepts and tools: including principles of Lean Thinking and Lean tools, as well as origins and cultural aspects critical to successful application within an organization.

- Measurement system analysis: including repeatability and reproducibility analysis, and long term measurement error.

- Process capability: including data transformation, life data analysis, and prediction.

- Root cause analysis: including matrix plots, multi-vary charts, hypothesis testing principles and methods, correlation and regression principles and methods.

- Experimentation: including principles of full and fractional designed experiments, planning and analysis using residuals, main effects and interaction plots, and approaches for model optimization.

- Identification and prioritization: including creativity tools such as the theory of inventive problem solving (TRIZ) and Pugh matrix.

- Failure mode avoidance: including system state flow, boundary diagram, interface analysis tables, fault tree analysis, robustness checklist, tolerance design and analysis, and principles and links between Failure Modes and Effects analysis for concepts, designs, processes.

- Sustainability and control: including control and reaction plans, and prevention controls.

Improvement Practitioner lean six sigma level 4 apprentices have the following skills:

- Leading improvement teams: Holding team members/stakeholders accountable for delivering agreed-upon actions within an improvement project and building/maintaining appropriate stakeholder relationships inside and outside the organization to deliver improvement project objectives.

- Strategic Deployment of Continuous Improvement: Contributing to the deployment of the improvement strategy, participating as an active member of the improvement community.

- Communication: Preparing and presenting concise proposals and plans. Capturing and sharing progress through effective formats and channels. Using and handling questions effectively. Building rapport with others.

- Capability Development: Training, facilitating, and critiquing the application of tools used by improvement practitioners, including tool selection, links between tools, how they are used within a structured method, analysis of results, and presentation of recommendations.

- Project Planning: Planning and managing finances, multi-stakeholder delivery, and benefits realization.

- Change Planning: Designing reinforcement, engagement, and communication strategies.

- Principles and Methods for Improvement: Guiding others on the selection of appropriate methods (e.g. Practical Problem Solving, Define-Measure-Analyse-Improve-Control, 8-Disciplines, Identify-Define-Optimise-Verify) to deliver improvements. Conducting gateway assessments to ensure the suitability of projects to progress.

- Project Selection & Scope: Guiding others on the selection and scoping of improvement projects and the initial response to product/process performance issues. Identifying, scoping, and prioritizing improvement opportunities that map to high-level organization objectives and key value streams.

- Process Mapping & Analysis: Guiding others on the selection of appropriate process mapping and analysis tools. Critiquing improved state.

- Lean Tools: Identifying and analyzing value streams using appropriate methods and tools to optimize flow to the customer. Developing a plan for Lean deployment within the organization, including effective and relevant performance metrics.

- Measurement: Guiding others on the planning, analysis, and interpretation of data collection and measurement studies, including the design of tests to recreate failures and steps to diagnose/reduce short and long-term measurement variation.

- Statistics & Measures: Confirming data and fit for a range of distribution models. Establishing predictions. Calculating confidence intervals.

- Data Analysis-Statistical Methods: Modeling random behavior and making inferences with levels of confidence. Calculating/recommending sample size. Testing hypotheses for all data types. Assessing input/output correlation. Generating, analyzing, and interpreting simple and multiple predictive relationship models.

- Process Capability & Performance: Identifying data stability/distribution issues and applying appropriate strategies to enable robust Capability Analysis. Analyzing life data to establish rates and patterns.

- Root Cause Analysis: Making appropriate use of data to assess the contribution of critical inputs/root cause(s) to product/process performance using appropriate graphical and statistical tools to draw and communicate conclusions.

- Experimentation & Optimization: Guiding others on the planning, analysis, and interpretation of experiments. Planning, conducting, analyzing, and optimizing both full and fractional experiments.

- Data Analysis-Statistical Process Control: Monitoring and assessing ongoing process variation and changes through chart selection, control-limit setting, sample sizing/frequency, and control-rules.

- Benchmarking: Guiding others on benchmarking to support all stages of improvement projects, including future-state design.

- Failure Mode Avoidance: Decomposing complex systems to define main functions. Analyzing system interactions. Cascading knowledge through fault tree analysis. Creating and assessing design rules, standards, and verification methods. Completing robustness studies to select appropriate control strategies and detection methods.

- Sustainability & Control: Guiding others on control and sustainability planning, including methods and tools to maintain benefits, extraction of learning, replication, sharing, and consolidation of new knowledge into organizational learning.

- Drive for results: Co-ordinates and delivers sustained improvement across the business by engaging with, and inspiring stakeholders; adopting a can-do attitude

- Team-working: Leads cross functional project teams proactively, regularly supports others and replicates learning

- Professionalism: Exemplifies high standard of professional integrity, ethics and trust within the organisation, whilst maintaining flexibility to the needs of the business

- Process Thinking: Drives process-thinking and customer-focused, data-driven decision making

- Continuous development: Identifies & models opportunities for development of self & others

- Safe working: Adopts a proactive approach to safety, encouraging others and suggesting compliance improvements

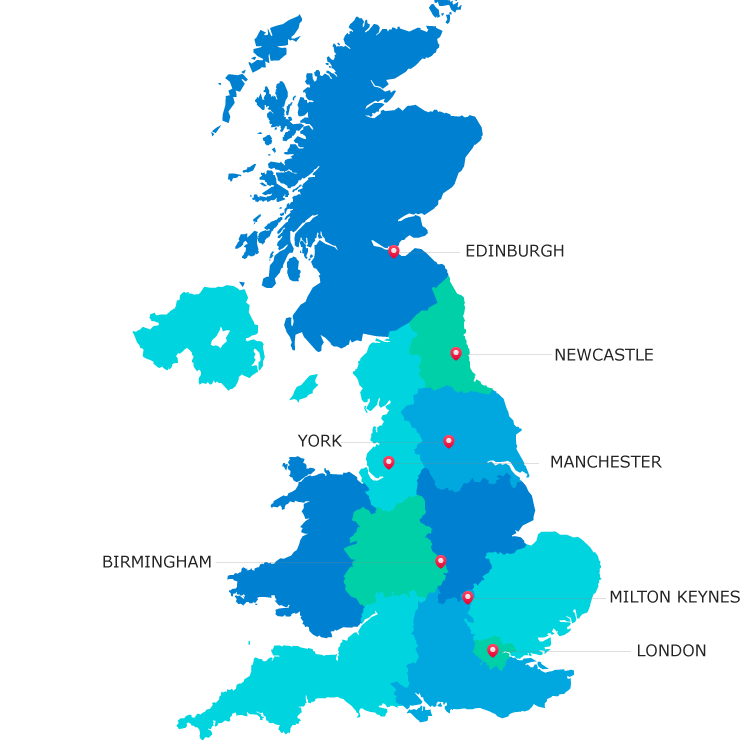

Our Most Popular Locations

Our Six Sigma, Lean and Kaizen classroom training is available in major locations, towns and cities across the UK. Here’s where we get the most demand.

Contact us

General Enquiries

Want to place an order, or need more information on one of our courses?

Live Chat

Want to place an order, or need more information on one of our courses?

- Start Chat

Our address

1 Parkview Court, St Pauls Road, Shipley, West Yorkshire, BD18 3DZ

- Company # 4407150 VAT # 801793338

Contact hours

Monday – Friday: 8.30am – 5pm

- Excluding public holidays